Workshop products made from stainless steels

SKM Stainless workshop in Leppävirta design and manufacture tanks, piping and components for equipment from stainless steel, acid-proof steel, duplex and superduplex, as well as other special material such as titanium and plastic.

Our workshop products consist of various pressure vessels, storage tanks, tanks for chemicals and flammable liquids, mixer tanks, silos, flue gas scrubbers, prefabricates for on-site built tanks, pipes, pipe parts, and pipeline prefabricates. All our products are delivered as complete deliveries, installed on site, from tailor-made prefabricates. Our operations are certified according to international standards ISO 9001, SFS-EN 764-5 and ISO 3834.

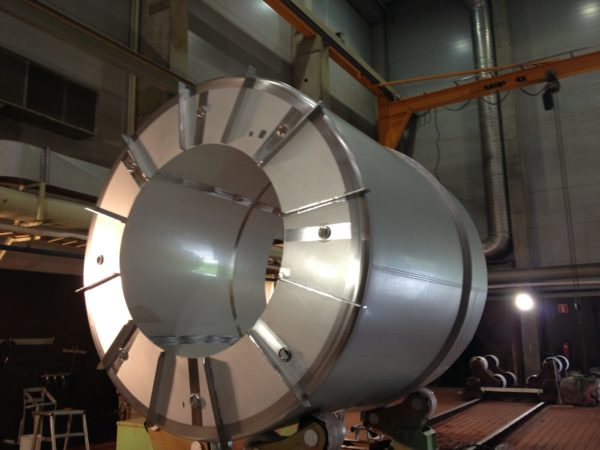

Pressure vessels and -equipment

SKM Stainless pressure equipment is designed and manufactured according to the standard SFS-EN 13445. Our main product line consists of pressure vessels, generally with a material thickness of less than 25 mm. Measured in number of pieces, workshop mainly produces small pressure equipment of just a few cubic meters, but we are also familiar with bigger pressure vessels. The largest pressure equipment manufactured at our workshop have weighed over 60 tons.

The manufacture of pressure equipment is regulated by various Finnish and European laws and regulations, such as the Pressure Equipment Act (1144/2016), the Government Decree on pressure equipment (1548/2016), the Pressure Equipment Directive 2014/68/EU (PED) and the Government Decree on pressure equipment safety (1549/2016). The design and manufacture process for pressure equipment is based on the essential safety requirements found in the Pressure Equipment Directive as well as its conformity assessment procedures that are required to assess the conformity of the manufacturing process. Completed pressure equipment or assemblies that are in conformity with all applicable requirements bear the CE marking. With this we can guarantee that all equipment we design and manufacture is in conformity with all safety regulations and that the assessment of conformity has been completed in accordance with all relevant regulations and laws.

Storage tanks

Storage tanks are typically either non-pressurized or very low pressure containers, and the basis of their design often comes from the relevant parts of the standard SFS-EN 14015. Storage tanks are not subject to government regulation, provided the content of the tank is harmless. The client can however if they wish have the design be subjected to a third party for structural design approval.

If the client does not have any special requirements regarding the normal technical specifications, we will generally use SKM Stainless’s own factory standards in the design of the structure and technical solutions. Storage tanks are typically made from thin materials, 3–10 mm of thickness. We also manufacture and install big storage tanks that are built on-site.

Tanks for chemicals and flammable liquid

Tanks for chemicals and flammable liquid can either be non-pressurized or pressurized. Third party approval of the structural design for chemical and flammable liquid tanks should be requested either by the manufacturer or the client. For these tanks we use standardized best practices from SKM Stainless’s own factory standards. Like the storage tanks, the wall thicknesses of the chemical and flammable liquid tanks are thin, around 3 –10 mm. Our production site has the capacity to manufacture tanks of big sizes also.

Agitator tanks

Agitator tanks are largely designed in accordance with the standard SFS-EN 14015. The strength analysis of the tanks is made with a FEM to ensure that agitator loads have been taken to account when choosing materials and deciding thicknesses. Agitator tanks are made according to both ready drawings and following our own design and factory standards. Our goal is always to create the best complete solution for our customers. Agitators are often acquired by our clients themselves, but they also can be included to our scope of supply. Agitator tanks range in size from tanks of a few hundred liters to prefabricated assemblies that are built at the construction site itself.

Silos

Silo design and manufacture generally follows the standard SFS-EN 1993-4-1 + AC. Silos are typically lightweight in relation to their volume, and as such weight is rarely a limiting factor when manufactured in our workshop or at the installation site. If possible, SKM Stainless’s own standardized construction practices are used in the design and manufacture of silos.

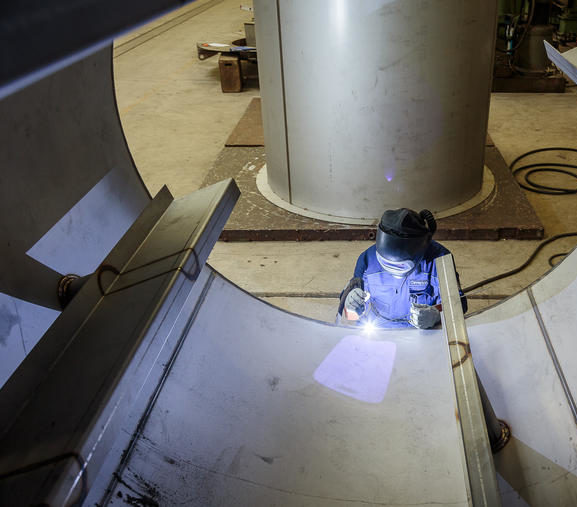

Scrubbers

Scrubbers are manufactured according to ready drawings from the clients as well as our own design. We do not offer process design for the scrubbers. There are no harmonized standards for scrubbers, which means the design most often is based on a review of several relevant manufacturing and inspection standards, according to the client’s needs. We make scrubbers in sizes from small units of a few cubic meters to much larger assemblies. The largest scrubber manufactured at SKM Stainless workshop in Leppävirta had a diameter of 8.5 m, a height of 20 m and weighed 30,000 kg.

Piping and pipe parts

SKM Stainless manufactures pipes according to the standard SFS-EN 10296-2 and the pipe parts according to the standards SFS-EN 10253-3 and SFS-EN 10253-4. In certain special cases it is also possible to manufacture pipes according to the standard SFS-EN 10217-7. Pipes and pipe parts are often also manufactured in conformity with other relevant standards

We primarily manufacture pipes and pipe parts in size DN600 and larger. We can also offer smaller pipes and pipe parts on a case-by-case basis. Our pipes and pipe parts can also be made out of special materials such as LDX, Duplex, Superduplex, titanium, 904L and SMO

Prefabricated pipe parts

We manufacture a large variety of prefabricated pipe parts, from small individual prefabrications to large prefabricated assemblies, in all diameters and materials. Our prefabricated pipe parts are delivered both to other manufacturers as well as our own construction sites. By utilizing high quality prefabrication techniques for pipes you can lower the total cost of installation for industrial piping by a significant amount. It is also much easier to maintain quality in a controlled environment at the workshop, as opposed to the changeable environment on-site.

Other process equipment, parts and components

SKM Stainless Oy also manufactures many other types of process equipment, parts and components such as various channels, cones, forms, pipe modules etc. out of any kind of steels or plastic material found in our material selection.

Spray pickling

SKM Stainless factory at Leppävirta has a spray pickling hall with pickling equipment. Spray pickling can be used to clean any stainless steel product with acid, but especially when it comes to larger pieces it is overwhelmingly the best way to ensure a flawless surface on the final product. SKM Stainless’s spray pickling hall can fit a product over 20 meters in length and 7 m in diameter in its entirety. Almost all of the products manufactured at the workshop are finalized with spray pickling. The spray pickling service is also offered to competitors and others in need of the service.